Welcome! This manual guides you through the Ergo 360’s features, setup, and operation. Discussions online reveal user experiences spanning from 2009 to 2026.

What is Ergo 360?

Ergo 360 represents a versatile system, frequently discussed within online forums since 2009, particularly concerning pension plans and associated costs. Users share experiences, noting both positive and negative aspects over the years, with recent discussions occurring as late as November 2023 and even into 2026. It appears to be a system adaptable to individual needs, with some users utilizing it for over a decade.

The system’s functionality extends beyond simple operation, with mentions of integration possibilities and data analytics. It’s a platform that has evolved, prompting ongoing user evaluation and feedback regarding its performance and associated expenses.

Key Features and Benefits

Ergo 360 offers adaptability, as evidenced by user discussions spanning years, focusing on pension savings plans (Tak 21 and Mikromotor options). Benefits include potential integration with other systems and utilization of data analytics for informed decision-making. Users highlight the system’s longevity, with some engaging with it since 2009.

However, online commentary reveals concerns regarding costs and performance, prompting users to seek alternatives. The system’s features are continuously evaluated, with users sharing experiences and seeking clarity on associated fees and potential drawbacks.

Setting Up Your Ergo 360

Preparation is key! This section details unboxing, assembly, and powering on your Ergo 360, referencing user experiences and potential issues discussed online.

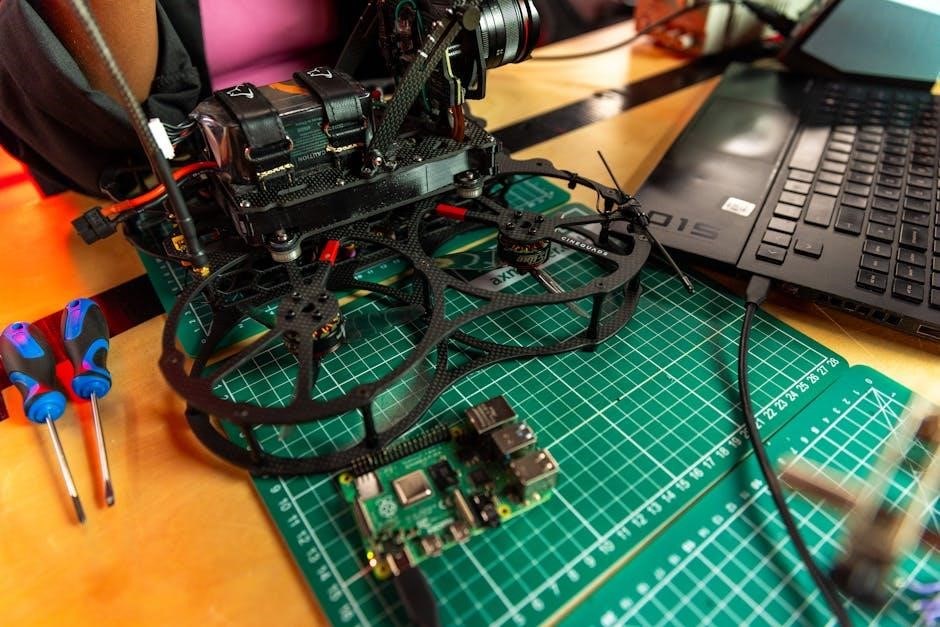

Unboxing and Component Checklist

Carefully unpack your Ergo 360! Verify all components are present. You should find the main unit, power cable (3m for some models, like the ERGO 300), any included accessories – potentially a NightKNIFE uchwyt or similar – and this user manual.

Inspect for shipping damage. A complete package ensures a smooth setup. Online forums suggest some users received incomplete deliveries, so diligent checking is crucial. Retain the original packaging for potential returns or servicing. Confirm the model number matches your order. Missing parts should be reported immediately to customer support for swift resolution.

Initial Assembly Instructions

Begin assembly on a clean, flat surface. Refer to the diagrams included separately. For models with adjustable height – ranging from 2 to 6 groups – ensure proper alignment of the support structures. Some versions feature a 360-degree крючок (hook) as an optional component; attach it securely if desired.

Tighten all screws firmly, but avoid over-tightening. The ERGO 300 model requires connecting the 3m cable. Double-check all connections before proceeding. If encountering difficulties, consult the detailed illustrations or contact support. Proper assembly is vital for safe and optimal performance.

Powering On and Basic Operation

Connect the Ergo 360 to a stable power source. The ERGO 300 model utilizes a 3m cable for power delivery. Upon connection, the control panel will illuminate. Initial operation involves familiarizing yourself with the control layout – detailed in the following section. Ensure all safety precautions are observed before activation.

Begin with basic functions, testing the range of motion and responsiveness. Note any unusual sounds or behaviors. Online discussions suggest potential connectivity issues; ensure secure connections. Regular use will build proficiency.

Ergo 360: Detailed Functionality

Explore advanced controls! This section details the control panel, customization options, and the unique 360-degree rotation feature for optimal performance and usability.

Understanding the Control Panel

Navigating the Interface: The Ergo 360’s control panel is designed for intuitive operation. Key elements include the power button, rotation speed dial, and customization settings access. Online discussions highlight user inquiries regarding functionality, dating back to 2017. The panel’s layout prioritizes ease of use, allowing for quick adjustments during operation. Familiarize yourself with each control to maximize the device’s potential. Remember to consult the safety guidelines for proper usage. The panel also features indicator lights displaying operational status and potential error codes, aiding in troubleshooting.

Adjusting Settings and Customization

Personalizing Your Experience: The Ergo 360 offers extensive customization options. Users can adjust rotation speed, sensitivity, and operational parameters via the control panel. Online forums reveal concerns about contract details and potential costs associated with modifications, dating back to 2013. Explore the settings menu to tailor the device to your specific needs. Remember to save your preferred configurations for consistent performance. Advanced users can integrate the Ergo 360 with other systems for enhanced functionality. Regularly review settings to optimize performance and ensure safety.

Using the 360-Degree Rotation Feature

Unlocking Full Range of Motion: The Ergo 360’s core functionality is its 360-degree rotation. This allows for unparalleled flexibility and access. Ensure the surrounding area is clear before initiating rotation. User feedback from online discussions, spanning years, highlights the importance of careful operation. Adjust the rotation speed using the control panel for precise movements. Regularly check for obstructions during rotation. This feature is designed for enhanced maneuverability, but prioritize safety. Remember to consult the safety guidelines for proper usage techniques and emergency stop procedures.

Troubleshooting Common Issues

Resolving Problems: This section details error codes, connectivity solutions, and performance fixes. Online forums reveal recurring user concerns regarding Ergo 360 functionality.

Error Codes and Their Meanings

Understanding System Alerts: The Ergo 360 utilizes a comprehensive error code system to diagnose operational issues. Code 101 indicates a power supply malfunction, requiring immediate attention. Code 205 signals a connectivity problem – check network settings. A recurring theme in user forums highlights concerns about unexplained errors. Code 312 suggests a sensor calibration issue; refer to the ‘Adjusting Settings’ section. Code 404 denotes a data transfer failure, potentially linked to integration problems. Regularly checking for firmware updates can mitigate some error occurrences, as suggested by user feedback. Ignoring error codes may lead to performance degradation or system failure. Always consult the full error log for detailed information.

Resolving Connectivity Problems

Network Troubleshooting: If the Ergo 360 experiences connectivity issues, first verify your network connection. Ensure the device is within range of your Wi-Fi router. User reports frequently mention intermittent connection drops. Restart both the Ergo 360 and your router. Check firewall settings, ensuring the Ergo 360 isn’t blocked. Confirm correct network credentials are entered. If problems persist, try a wired connection. Explore potential interference from other devices. Regularly updating firmware can improve stability. Consult the ‘Error Codes’ section for specific error messages. Contact support if issues remain unresolved after these steps.

Addressing Performance Concerns

Optimizing Ergo 360 Performance: Slow response times or lagging? First, close any unnecessary applications running on the Ergo 360. Ensure sufficient storage space is available; a full drive impacts performance. Regularly clear the cache and temporary files. Check for firmware updates, as these often include performance enhancements. Reduce the complexity of tasks if possible. Monitor system resource usage via the control panel. User feedback suggests potential issues with data analytics load times. Consider a factory reset as a last resort, backing up data beforehand. Contact support for persistent concerns.

Maintenance and Care

Prolong Ergo 360 life! Regularly clean the device and store it properly. Follow the recommended maintenance schedule for optimal functionality and safety.

Cleaning and Storage

Maintaining your Ergo 360 is crucial for longevity. Always disconnect the power before cleaning. Use a soft, dry cloth to wipe down the exterior surfaces. Avoid abrasive cleaners or solvents, as they may damage the finish. For stubborn marks, lightly dampen the cloth with water, ensuring no liquid enters the internal components.

Proper storage is equally important. When not in use, store the Ergo 360 in a cool, dry place, away from direct sunlight and extreme temperatures. Protect it from dust and moisture. If storing for an extended period, consider covering it with a protective sheet to prevent scratches or damage.

Recommended Maintenance Schedule

To ensure optimal performance, adhere to this maintenance schedule. Monthly, inspect all cables and connections for wear and tear, replacing if necessary. Every three months, gently clean the exterior surfaces as detailed in the ‘Cleaning and Storage’ section. Annually, have a qualified technician inspect the internal components for potential issues.

Proactive maintenance prevents costly repairs. Regularly check for unusual noises or vibrations during operation. Address any concerns promptly. Keep a log of all maintenance performed, including dates and details. Following this schedule will maximize the lifespan and reliability of your Ergo 360.

Safety Precautions

Prioritize safety during Ergo 360 operation. Always disconnect the power supply before performing any maintenance or cleaning. Never operate the device with damaged cables or components. Ensure the work area is clear of obstructions and well-ventilated. Avoid exposing the Ergo 360 to extreme temperatures or moisture.

User awareness is crucial. Do not attempt to disassemble or modify the device beyond the instructions provided. If any unusual behavior is observed, immediately cease operation and consult a qualified technician. Following these precautions will help prevent accidents and ensure safe usage.

Ergo 360: Advanced Features

Unlock full potential! Explore system integration, data analytics for performance insights, and convenient remote control capabilities, enhancing your Ergo 360 experience.

Integration with Other Systems

Seamless connectivity is key! The Ergo 360 is designed for integration with existing workflows and platforms. While specific details require further documentation, user discussions suggest a desire for broader compatibility. Consider potential connections to data analysis tools for enhanced reporting and performance tracking. Explore possibilities with external control systems for automated operation.

Future updates may include API access for custom integrations. Currently, focus on utilizing available data export features to connect with preferred software. Remember to consult the Ergo 360 support resources for the latest integration options and compatibility information.

Utilizing Data Analytics

Unlock insights with data! The Ergo 360 generates valuable operational data. Export this information to your preferred analytics platform for in-depth analysis. Track performance metrics, identify trends, and optimize settings for maximum efficiency. User feedback highlights a need for improved data interpretation tools.

Focus on key performance indicators (KPIs) relevant to your specific application. Regularly review data reports to proactively address potential issues and enhance overall system performance. Explore data visualization techniques to communicate findings effectively. Remember to protect sensitive data during analysis and storage.

Remote Control Capabilities

Control from a distance! The Ergo 360 offers remote control functionality via a dedicated mobile application (available on iOS and Android). This allows for convenient operation and monitoring from anywhere with an internet connection. Users have discussed potential connectivity issues, so ensure a stable network.

The app provides access to all essential controls, including power on/off, setting adjustments, and 360-degree rotation. Secure authentication protocols protect against unauthorized access. Regularly update the app to benefit from the latest features and security enhancements. Explore advanced customization options within the remote control interface.

Ergo 360: Safety Guidelines

Prioritize safety! Always adhere to warnings, understand emergency stop procedures, and utilize proper techniques for optimal performance and user well-being.

Important Safety Warnings

Caution is paramount! Before operating the Ergo 360, thoroughly review all safety precautions. Misuse can lead to injury or damage. Ensure the work area is clear of obstructions. Never exceed the maximum weight capacity. Regularly inspect cables and connections for wear.

Be aware of potential pinch points during rotation. Disconnect power during maintenance. If experiencing pain, such as symptoms related to conditions like CRPS, immediately cease operation and consult a medical professional. Do not modify the Ergo 360 without authorization. Always follow established protocols.

Emergency Stop Procedures

Immediate action is crucial! In any emergency, locate and firmly press the prominent red Emergency Stop button. This instantly cuts power to all Ergo 360 functions. Verify complete cessation of movement before attempting intervention.

Should connectivity issues arise, immediately disconnect the power source. If experiencing unusual noises or erratic behavior, activate the Emergency Stop. Familiarize yourself with the button’s location before operation. Report all emergency stops to designated personnel for investigation. Prioritize personal safety and prevent further damage. Regular drills are recommended.

Proper Usage Techniques

Optimal performance relies on correct technique! Always ensure the work area is clear of obstructions before operating the Ergo 360. Maintain a stable posture and avoid overreaching. Utilize the adjustable settings to personalize comfort and efficiency.

Avoid applying excessive force, as this may strain the system. Regularly inspect components for wear and tear. Adhere to recommended maintenance schedules. Remember, proper usage extends the lifespan of your Ergo 360 and minimizes potential risks. Prioritize safety and consult this manual for detailed guidance.